EMC

Technical Note EMC

Technical Note

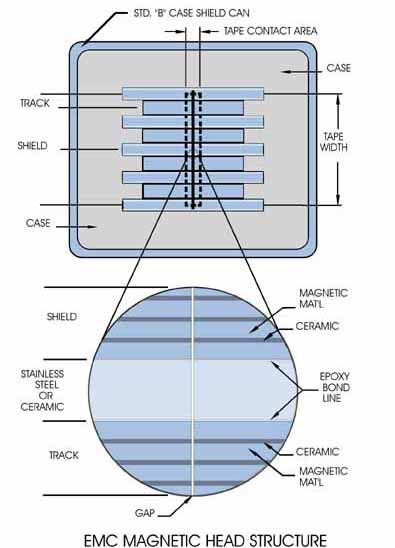

MAGNETIC HEAD

STRUCTURE

All EMC long life, high performance

magnetic heads are made with the same materials, processes and construction techniques.

The general design features are similar for all EMC heads from the smallest cassette heads

to the largest motion picture sound heads. The attached drawing of the EMC magnetic head

structure points out some of these features using a four channel, 1/4" cartridge head

as an example.The patented magnetic material used in both the track and shield

structures is a ceramic bonded stack of Hy Mu 800 magnetic material. The ceramic provides a long wearing surface for the tape to ride on and the Hy Mu

800 provides a high quality magnetic path for the magnetic flux to follow during either

the recording or playback function.

Stainless steel or ceramic spacers are used as separators between the track and shield

sections. The spacers are epoxy bonded to the magnetic material and this thin bond line is

the only epoxy present in the tape contact area. The case of the head may be made from

aluminum or brass while the shield can is Hy Mu 800 magnetic material. The

materials for the case and shield

can are completely outside the tape contact area and therefore do not affect the

head performance or interact with the tape in any way.

The EMC magnetic head structure was designed for extreme environments that have wide

variations in temperature and humidity and that have severe shock, vibration and

acceleration requirements. The passive magnetic material, ceramic and stainless steel used

in the tape contact surface is ideal for applications where the tape is left in static

contact with the face of the head for extended periods of time. Chemical reactions do not

readily occur between these passive materials and corrosive elements that may be released

from the compounds used to make up the magnetic tape whether in an inert atmosphere

environment or in an environment with extremely high humidity.

The EMC magnetic head structure was designed to minimize the amount of epoxy in contact

with the tape. As shown in the attached drawing there are only 16 epoxy bond lines in the

tape contact area. Conventional head designs have between 132 and 248 epoxy bond lines in

contact with the tape. These bond lines promote friction between the tape and the head

surface. In addition, foreign material can adhere to the soft epoxy structure and cause

spacing losses between the tape and the head.

This technical note describes the general features used in the design of the tape

contact surface on the face of EMC magnetic heads. Questions regarding this technical note

or other aspects of EMC magnetic head design should be directed to EMC

Engineering at 800

200 7850.

INSTALL EMC HEADS AND EXPERIENCE THE LONG LIFE,

ELECTRICAL EXCELLENCE

AND MAINTENANCE FREE PERFORMANCE YOU HAVE BEEN LOOKING FOR.

|